Level Sensor for Solids

By Megha Parolkar on November 12, 2019

BeginnerIntroduction

Level sensor caters to variety of manufacturing processes to fulfill demand of quality assurance, accuracy and production improvement by identifying the level of application media like solid or liquid. This article specifically covers the variety of level instruments used for different types of solids and the parameters that would be remember while choosing the right level sensor for process material of solid.

Selection: Application Media

Different types of level instruments are available for level detection but before selecting the sensors, the exact type of application media should be known for betterment of output and process.

- Bulky Solids

- Granular Solids

- Powder Form

Bulky Solids

The process media which includes heavy weight materials like limestone, coal etc. are known as bulky solids. These types of application material required level instruments with rigid support to resist the higher weight.

Factors Affecting

High Temperature - The bulky material like limestone, coal etc. are used in manufacturing processes where the temperature exceeds to high level. Level measuring devices with temperature endurance is better option to withstand in process.

Examples

Coal

Limestone

Stones

Recommended Products

SLA Dot Display

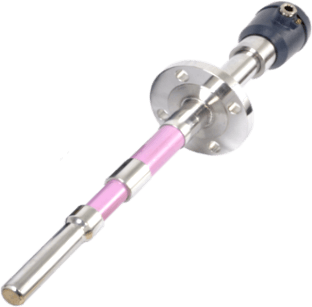

RF Admittance Level Sensor

Suitable for longer distances between probe and evaluation unit.

SLA Bar Display

RF Admittance Level Sensor

Suitable for materials that are prone to absorbing materials.

SLA Series

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

Vibrosonde

Vibrating Rod Level Sensor

Compact level limit switch for free-flowing as well as for bulky solids.

Granular Solids

The collection of free flowing particles like grains, sugar etc. are known as granular material. The size of granular material vary with the application media. The grain size plays an important role while choosing the vibrating forks level sensors.

Factors Affecting

Grain Size - The most important factor that should be considered while selecting the level instruments for granular material. For choosing the vibrating forks series the maximum grain size should be 12 mm not more than that.

Moisture Content - 7-10% of moisture content should be considered for recommending the level instruments in granular materials for providing better accuracy and output.

Examples

Wooden Chips

Sugar

Coffee

Recommended Products

Vital

Vibrating Fork Level Sensor

Vibrating fork level switch for free-flowing solids, granules and powders.

Vibrosonde

Vibrating Rod Level Sensor

Vibrating rod type level switch for free flowing solids and grains.

Orbit

Rotating Paddle Level Sensor

Stepmatic rotary paddle level switch used in most of the powders and granular solids.

Capvel-ICT

Capacitance Level Sensor

Capacitance based level transmitter used for continous monitoring of grains and powder.

Powder

The powder form is also a class of granular material in which particle size are very small. The granular material are crushed or grinded to make the powder form.

Factors Affecting

Stickiness - Some powder create coating on the level sensors as it contains some moisture during processing of material so it will be benificial to choose level sensors that are immune to build-up.

Examples

Flour

Spices

Milk Powder

Recommended Product

Vital

Vibrating Fork Level Sensor

Vibrating fork level switch for free-flowing solids, granules and powders.

Orbit

Rotating Paddle Level Sensor

Stepmatic rotary paddle level switch used in most of the powders.

Coat-Endure

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

SLA Series

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

More articles on Intro Level Sensor