Point Level Switch

Level sensors are integrated with automation systems to manage the flow of production operations. Level sensors are also known as level instruments which are considered one of the most demanding devices to ensure workplace safety and support inventory management systems. The level measuring instruments are combined with electronics circuitry to acknowledge overspill conditions which are currently known as point level sensors. The point level sensors are generally considered over continuous level transmitter as a backup process to avoid material loss. Sapcon has been manufacturing point level switches in India since its beginning and frequently improve its level measuring devices as every year passes.

Point level measurement is the process where a point level switch is used to monitor the presence of application media stored in Tanks, Containers, Silos, and Hoppers. As the name implies, point level sensors trigger an alarm at a predefined point when the material is identified. This process of level detection is known as point level detection.

Categorization based on Principles

Advancement in level detection method appeal point level sensors to be classified over wide categories based on principles, output, application media, etc. The following are the list of point level sensor categorization based on an array of principles:

Vibrating Fork

Applications: Solids, Liquids, Powders, and Granules

Capacitance

Applications: Solids, Liquids, Slurries, Powders, and Granules

Admittance

Applications: Sticky Solids, Pastes, Liquids, Slurries, and Powders

Vibrating Rod

Applications: Solids, Granules, and Powders

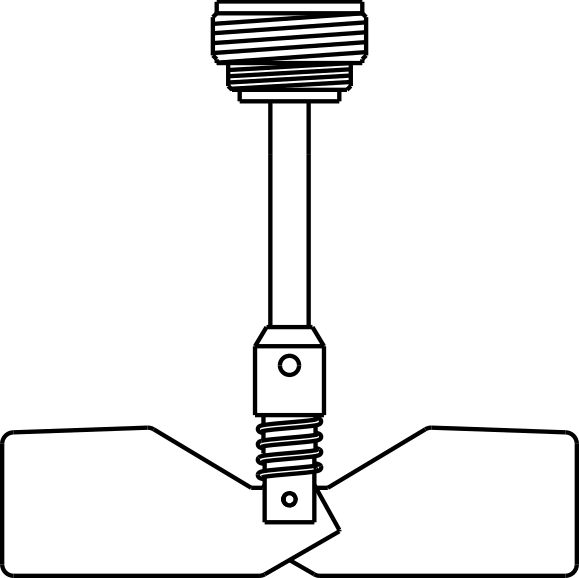

Rotating Paddle

Applications: Solids, Granules, and Powders