Operating Principle

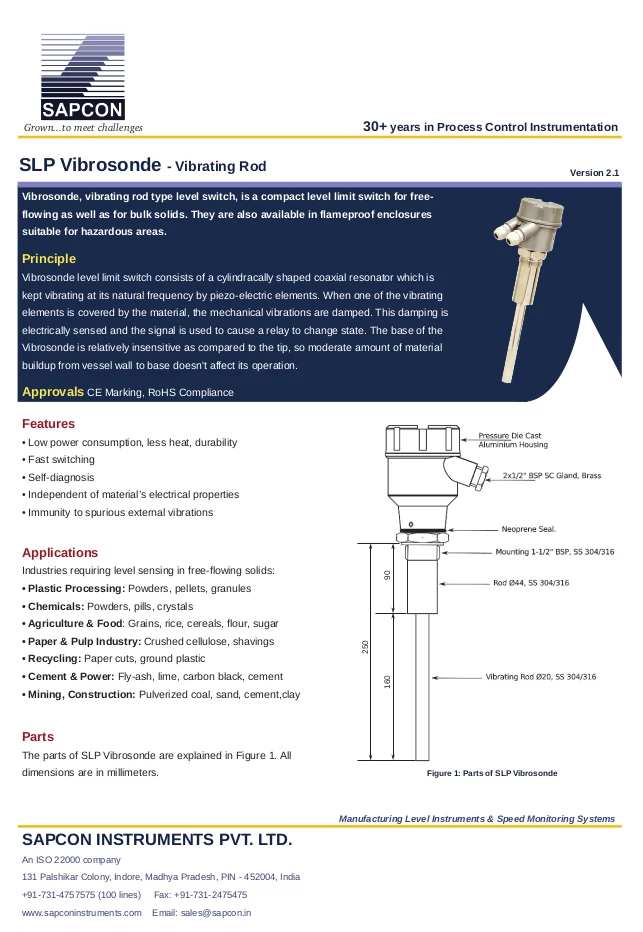

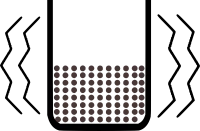

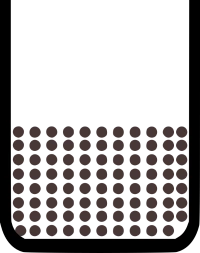

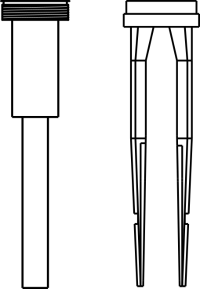

The working principle of the rod type level switch is based on continuously vibrating a mechanical rod at its natural frequency. The working principle of the rod type level switch is the same as the vibrating fork level switch. The only difference is that a vibrating rod kept vibrating instead of tuning fork. A vibrating rod is kept in mechanical vibrations at its resonance frequency by piezo-electric crystals. When the service material covers the rod probe, vibrations are damped which is sense electronically and processed signal is used for switching.

Benefits

Designed & Manufactured in India

In-house Research and Development keeps pace with new age applications, outputs and standards

Calibration-free

No calibration feature in rod type level sensor makes installation effortless.

Proven Performance

Fruitful performance in powder and granular applications where tuning fork breaks down.

No Moving Parts

No moving parts in rod level sensor makes it maintenance-free and free from wear and tear.

Low Power Consumption

Lower heat dissipation in rod level switch makes it suitable for longer life span.

Insensitive to Tank Vibrations

Special algorithm for detecting switching condition ignores vibrations induced on the tank during material flow.

Indepedent of material's dielectric properties

Depends only on viscosity and specific gravity of application media.

Better Immunity to Buildup than Vibrating Forks

A single vibratory element is exposed to application media, it helps in reducing the tendency of raw material to build-up between vibrating fork tines.

Applications

Grain Handling

Grain handling and management are required to remove impurities and broken pieces and keep stored grain in good condition. This processing includes bulk raw material handling which needs rigid level measuring devices to withstand in a sturdy situation. The overall process is lengthy.

Vibrating rod level sensor is ideal match to handle these type of operations. It comprised of sturdy rod with flameproof enclosure to bear harsh conditions.

Fertilizer & Pesticides

Fertilizers and pesticides are used to beat bacterial infections, improve crop quality, and are essential for plant growth. The manufacturing of fertilizers includes chemicals like nitrogen, potassium, and ammonia. These concentrated nutrients should be monitored carefully.

Our vibrating rod level sensor is independent of the material's dielectric property which makes it perfectly suitable for the production of pesticides to give proficient output independent of any chemicals and also immune to external vibrations.

Man-made Fibre

To improve the sustainability of the resultant product, the man-made fiber industry is continuously surviving in this competitive era. By using state-of-the-art methods, the manufacturing process divides its operations into batch which consumes a huge amount of power.

Our rod level sensor is available with a low power consumption feature that saves power and cost. The customized probe configuration helps to select the probe length according to the requirements that even fits in small containers.